Interview with Trend Garden | Benelux Companies showing Resilience

Benelux companies in China are operating under COVID19 measures. What have been the impact of these measures and how are companies doing at this time? With a series of interviews of the Benelux of Commerce business community, we aim to share the stories of Dutch, Belgium, and Luxembourg entrepreneurs in the South of China (PRD/GBA).

Company: Trend Garden

Location: Foshan, Guangdong

I am Thomas Broertjes and I arrived in Guangzhou in January 2007. With my University not finished, I knew that I had to grab this opportunity in China with 2 hands. I worked for a Dutch trading company, specialized in stainless steel furniture, but in 2009 I was given the opportunity to work for a Danish Manufacturer of stainless steel garden furniture and in 2012 I bought shares in the company. We are a company that is aiming for the exclusive market and most of our products are being sold in Europe, especially Germany. Besides that, I have been married for 10 years and have a daughter of 10 years old and a son of 6 years old.

1. What has been the impact of the Coronavirus on your company and business?

At this moment this is difficult to say. In the short term, we can see that our customers are ordering less for the upcoming season. We also see that new developments for next year are not being created. In the long run, we need to see how this summer will be and how Europe is handling the COVID-10 situation. We do see that other manufacturers are facing difficulties and we are preparing for that as well, but we can only see the damage in August and September, but we, in general, we have long term customers and we have a very good relationship with them, so in the end, we will always try to work things out together and make it work for all of us.

2. What kind of government regulations did you have to implement?

Most of the communication was with the local neighborhood department. We are in a relatively small neighborhood, so communication went smooth and we have a WeChat group with the local Committee and they kept us informed. We had to implement all the requirements that every company had to take (stock of mouth caps, disinfect, 3x daily check of the temperature of workers, isolated area if infection occurred, manual for meetings, production and for emergencies. Once we showed everything we were allowed to start production again.

3. How did you start-up your business again and on what capacity have you been operating?

In fact, we were lucky. Last year we had to downgrade our company and reduced the amount of employees and reduced our factory space. So with a small workforce, we were quite quickly back in business. All different departments had still enough work to do and we were able to be back on track relatively fast. We started on the 18th of February with 40% but on the 1st of March all workers were back.

4. What kind of business activities can and can you not do at the moment?

Normally in this period, we finalize the new developments for next year with our customers. They come to our factory and modify and confirm the new samples. This is now not possible. In our market 2mm can make a difference in the comfort of a chair, so it is always important to get this feedback. Now, most of the new developments are put on hold. This is also because the customers in Europe are not able to promote these new items on shows or invite their customers to their display of new items. Besides that, we are able to produce as normal.

5. What are your expectations for the coming months and this year?

It’s going to be a challenge for sure. For us, it depends on the upcoming months and how fast Europe can go back to “normal”. For sure this will have a big influence on all countries and not only on the economy. But different situations also create new opportunities, so we just face what comes on our path and make the best out if, because there are too many scenarios possible to make a plan for the very long run.

Our entrance was the last to be reached, before the area was closed off.

17th of February: First meeting after we were allowed to be open again.

3rd of March: Production is back on track

15th of April: Work is still filling the factory

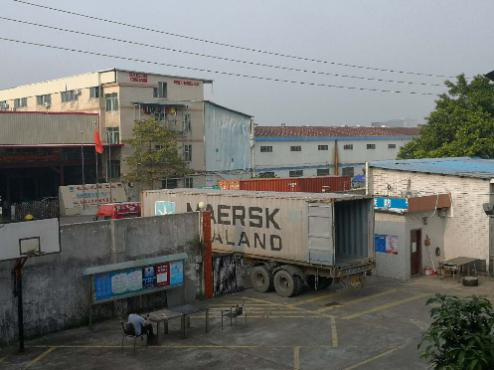

16th of April: Multiple container loadings.